Die technologische Wirkung von Kohlefaserverbundträgern untergräbt die Tradition!

In recent years, carbon fiber composite beam technology has set off a wave of innovation in the machinery and equipment industry. Traditional metal beams have certain limitations in terms of load-bearing capacity and weight, and the emergence of carbon fiber composite beam technology has completely changed this situation.

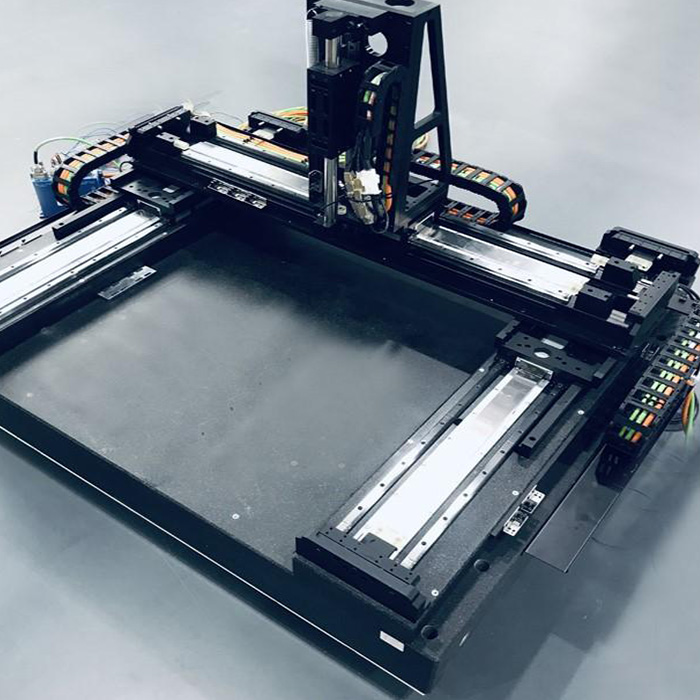

CNC machine tools are the foundation of today's industry and are mainly used in all walks of life. The gantry structure machine tool is an important structural form of CNC machine tools, and the beam is the basic structural component that makes up the movement of the machine tool. The static and dynamic characteristics of the beam itself determine the overall performance of the gantry machine tool, and have an important impact on the processing efficiency, accuracy and stability of the machine tool.

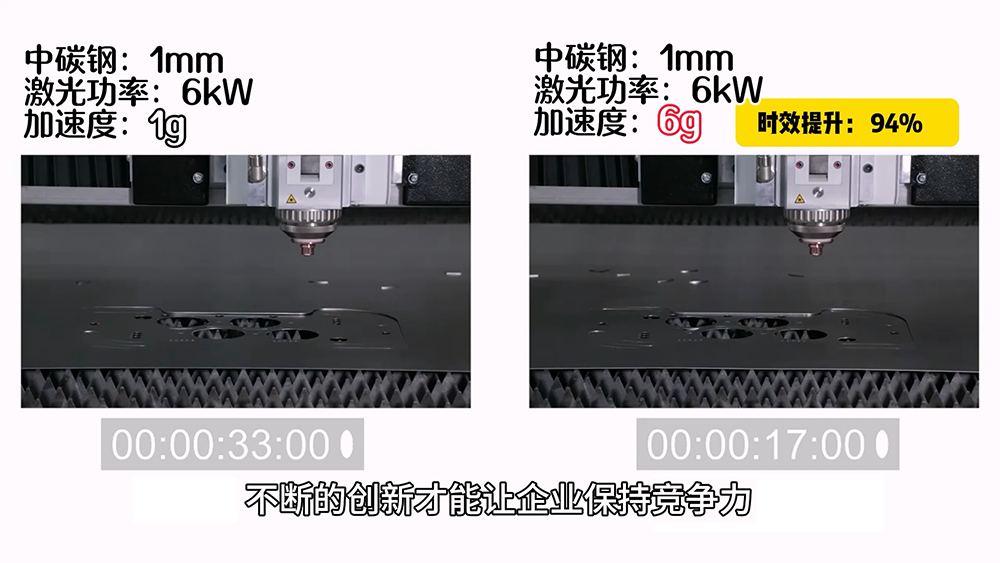

At present, the beams of machine tools are mostly made of metal, mainly steel and aluminum alloy. Machine tools that do not require high movement speed are made of steel, which has good stability and high precision. However, for machine tools that require high motion speed and acceleration, such as laser cutting machine tools, robots, etc., when the dynamic characteristic matching exceeds the limit, the performance cannot be further improved. Therefore, such high-speed motion machine tools usually use aluminum alloy beams. However, the weight of the aluminum alloy beam is still too large. At the same time, the aluminum alloy material has low modulus, is soft, is easy to deform, has limited improvement in high speed and acceleration, has a large thermal expansion coefficient, and temperature changes affect accuracy, so accuracy and speed cannot be achieved at the same time.

Carbon fiber is an inorganic fiber material with high precision and high modulus. The specific gravity is only 1.6, and the modulus exceeds 230GPa, which is close to steel and much lighter than steel. Its main component is carbon, which is an inorganic brittle material. Carbon fiber has no plastic deformation and has an elongation at break of about 2%. Usually to achieve the same effect, the weight of parts made of carbon fiber is 1/4 to 1/5 of steel and 1/2 to 1/3 of aluminum alloy. Relying on the high-precision performance of carbon fiber materials, carbon fiber beams can greatly improve the motion performance of machine tools. With the same configuration, the machine tool acceleration can be easily increased to 4g, and the overall processing speed can be increased by 50-60%, achieving a significant jump in production efficiency. At the same time, carbon fiber beams also show obvious advantages in control accuracy. Its accuracy per meter can reach U level, and due to its extremely high strength physical properties, it can stably maintain high accuracy for a long time, providing users with more reliable and precise processing solutions. Therefore, it is very suitable for machine tools that require structural parts with good rigidity, high movement speed, and good dimensional stability.

First, the carbon fiber composite beam process has excellent strength and stiffness, allowing it to withstand greater loads while being relatively lightweight. This feature makes the mechanical equipment more stable and reliable during operation, and largely improves work efficiency.

Secondly, the carbon fiber composite beam process has excellent corrosion resistance and wear resistance. Compared with traditional metal beams, carbon fiber composite beams are less susceptible to corrosion and wear and can operate stably for a long time in harsh environments, extending the service life of mechanical equipment.

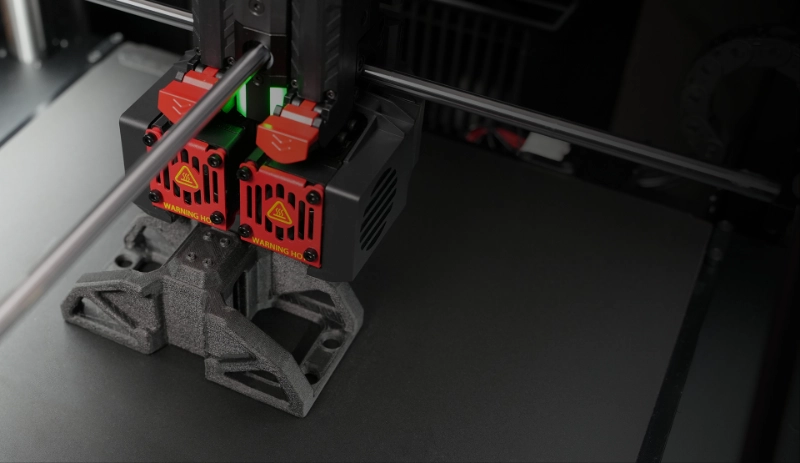

In addition, the carbon fiber composite beam process also has good design freedom and plasticity. Through the flexible use of beam design and manufacturing processes, more complex and sophisticated structures can be achieved to meet the needs of different mechanical equipment and improve overall performance.

Hithunder (Shenzhen) Carbon Fiber Technology Co., Ltd., as an important enterprise in carbon fiber composite beam technology, is committed to promoting the application of this technology in the machinery and equipment industry. The company has a professional R&D team that continuously innovates and optimizes processes to ensure stable product quality and performance.

If you want to know more about the carbon fiber composite beam technology, please visit the official website of Shenzhen Hithunder Carbon Fiber Technology Co., Ltd. There you will find out more about the application and success stories of this process, as well as our contact details. Let us work together to promote the development of carbon fiber composite beam technology in the machinery and equipment industry and bring more innovations and breakthroughs to the industry!