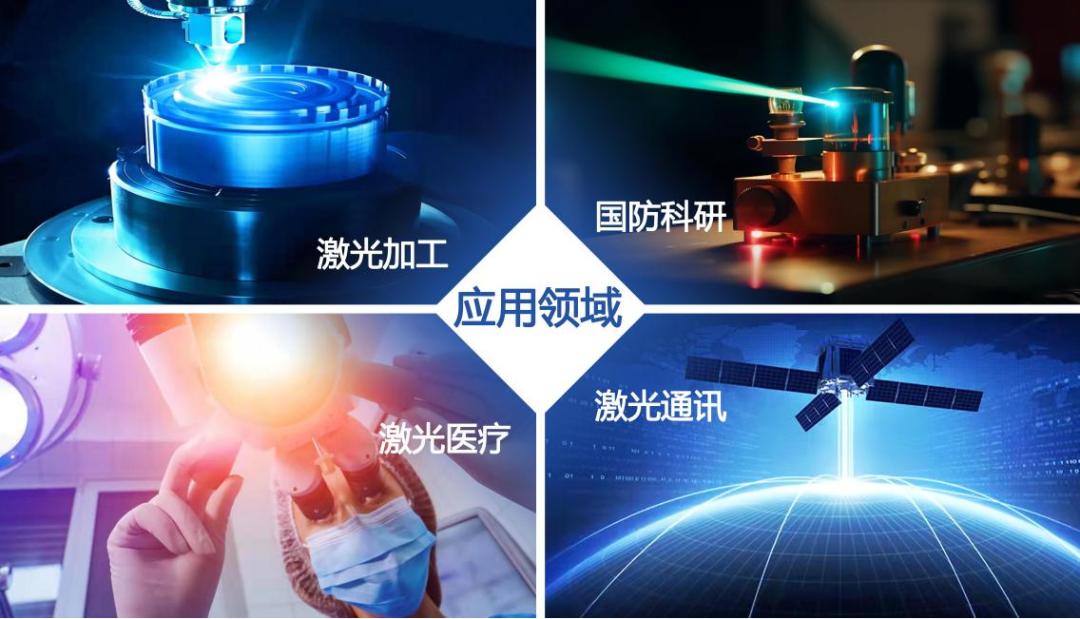

Die Welt' S erster Laser wurde in den 1960er Jahren geboren, und jetzt, nach mehr als 60-Jahren der Entwicklung, Laser sind weit verbreitet in den Bereichen Herstellung und Verteidigung Forschung verwendet worden. Laser werden als "das schnellste Messer und das genaueste Lineal" gefeiert, und die Leistung des "Messers" bei Verwendung und die Genauigkeit des "Lineals" beim Messen hängen eng mit der Leistung des Lasers zusammen. Daher ist es notwendig, ein Laserleistungsmesser zu verwenden, um die Leistung des Lasers zu messen, um die Genauigkeit von Laseranwendungen sicherzustellen.

Ein Laserleistungsmesser ist ein Instrument zur Messung der Ausgangsleistung einer Laserquelle. Ob es sich um eine schwache Lichtquelle (wie Fluoreszenz) oder einen hochenergetischen gepulsten Laser handelt; Ob es die Leistung eines kontinuierlichen Lasers oder die durchschnittliche Leistung eines gepulsten Lasers innerhalb eines bestimmten Zeitraums misst. Solange die Leistung des emittierten Lasers gemessen werden muss, wird ein Laserleistungsmesser benötigt. Daher ist ein Laserleistungsmesser ein unverzichtbares Messgerät in Laboren, Produktionswerkstätten und anderen Anwendungsumgebungen.

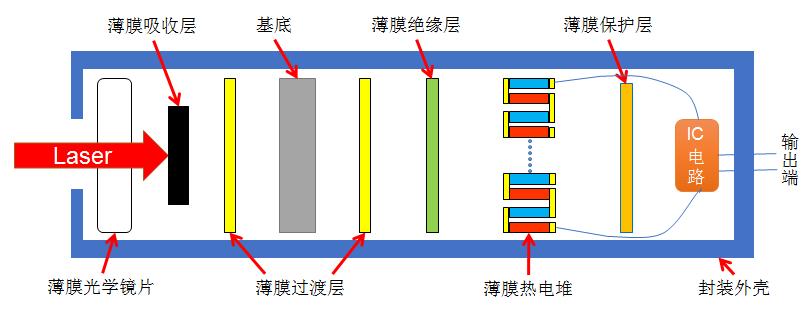

A laser power meter generally consists of a measuring part (pointer) with control and indication reading functions and a sensor part (probe). The two are combined to form a "measurement system." The probe can also be directly connected to the PC through an RS-232 serial port, RS-485 serial port, or USB virtual serial port for data reading, statistics, and storage. The main types of probes currently used on the market are: thermopile probes.

Thermocouple probe principle: The laser hits the membrane layer on the surface of the probe, is absorbed and converted into heat, the heat is transferred to the thermocouple and forms a temperature gradient field, the thermoelectric pile inside and outside the two nodes due to the temperature difference to produce a thermoelectric potential, the size of the thermoelectric potential is proportional to the amount of heat converted by the incident light.

How to choose a laser power meter: The laser power meter is composed of a pointer and a probe. Therefore, when choosing a laser power meter, it is necessary to choose the appropriate pointer and probe according to your own needs and the characteristics of the laser to form a set of suitable laser power meters for your own use. Therefore, it is recommended to choose from the following two aspects:

Select the appropriate probe according to the parameters of the laser:

(1) Power: The power of the laser should be less than the maximum measurable power of the probe. If the power of the measured laser is greater than the maximum measurable power of the probe, it will cause irreversible damage to the probe.

(2) Wavelength: The measurable wavelength range of the probe should cover the wavelength of the laser. If the measurable wavelength range of the probe does not cover the wavelength of the laser, there will be a deviation in the measurement results.

(3) Spot size: The area of the spot formed by the laser should be less than the absorption area of the probe, otherwise, when the probe measures the power of the laser, due to the fact that part of the laser is not absorbed by the absorption body of the probe, it will cause a deviation in the measurement results.

(4) Power density and energy density: The power density and energy density of the laser should be less than the damage threshold of the probe. Otherwise, during the measurement, it will cause irreversible damage to the absorption body of the probe, resulting in a deviation in the measurement results.

Select the appropriate data display method according to application requirements:

(1) Display data through the pointer: The pointer is the most common display tool and can be combined with all probes, suitable for the vast majority of scenarios.

(2) Transmit data via USB to the computer: The circuit is integrated in a small package, which is easy to use and can be directly connected to the PC via a USB interface. The PC software can be used to control the probe and process the data, which is convenient to use and has a wide range of application scenarios.

(3) Transmit data via serial port to the computer: The measurement data is transmitted through the RS-232 serial port or RS-485 serial port or USB virtual serial port of the computer. It is mainly used for integrated probes to realize online monitoring of laser power. Since the integrated probe needs to be integrated into the laser equipment, its size is relatively small and easy to install on the equipment. If used with a pointer, the floor space is large and it is not convenient to use.

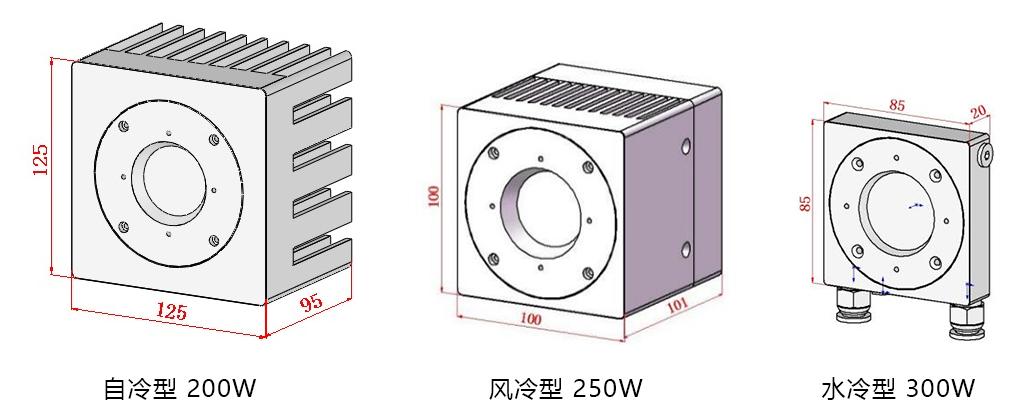

Choose according to the usage environment: Generally, power meters are used in production workshops, laboratories, or integrated into equipment. In some cases, there may be certain requirements for the size of the probe, cooling method, etc. However, the size of the probe is affected by its heat dissipation capacity. When the maximum power that the probe can withstand is increased, the volume inevitably needs to be larger or a better cooling method needs to be replaced. At present, the cooling methods of power meter probes mainly include natural cooling, fan cooling, and water cooling. Generally, under the same power, the volume of the water-cooled probe is the smallest, followed by the fan-cooled probe, and the volume of the naturally-cooled probe is the largest. Fan-cooled probes require a power source, and water-cooled probes require coolant. Therefore, different cooling methods have advantages in different power ranges, and the appropriate probe can be selected according to the application conditions.

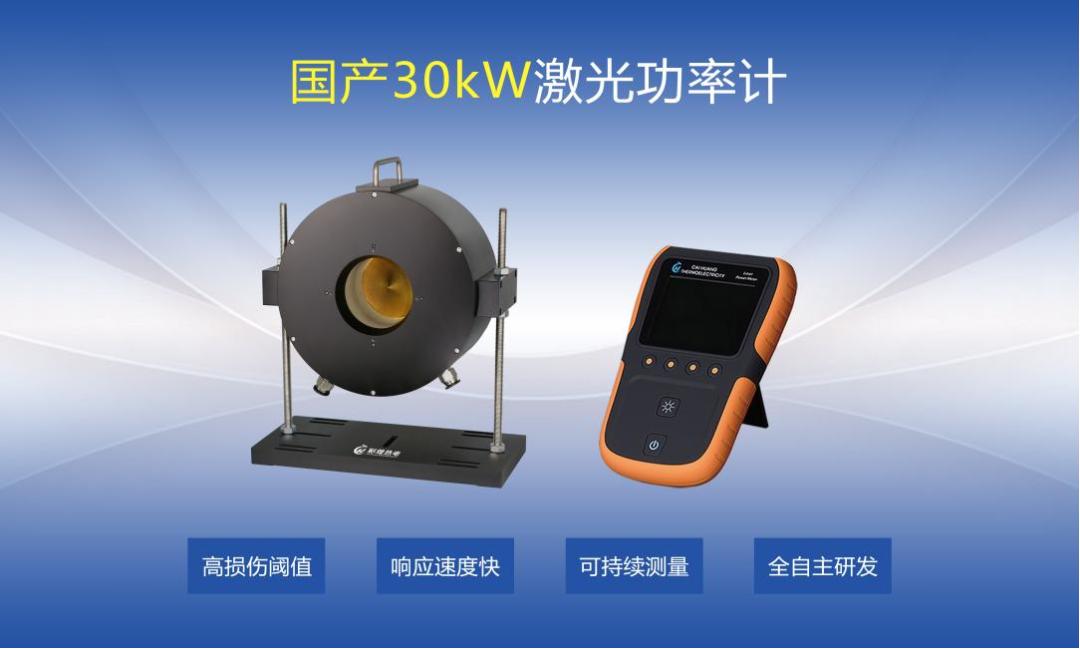

In general, when choosing a laser power meter, you can choose according to the parameters of the laser light source, the display method of power, and the application scenario. In addition, you can consult the power meter developer, such as providing your measurement needs to Colorful Thermal, and they will provide you with the best solution. If the conventional product cannot meet your needs, Colorful Thermal can provide a customized solution.